Dural Durabase CI++ Decoupling Mat 10m2 Roll

SKU: CI#1000/30-10P (10m²)£70.50 Incl. Vat

Pay with 3 interest-free instalments £23.50 using klarna

Pay with 4 interest-free instalments £17.63 using Clearpay

Express Delivery availabe for UK Mainland

In stock

Description

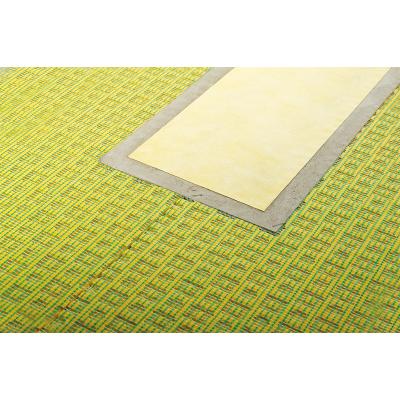

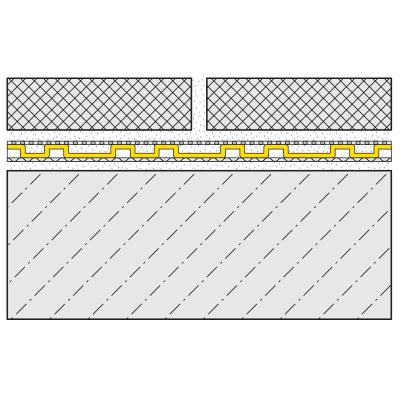

DURABASE CI++ matting in conjunction with tiles serves to decouple the tiles and bridge any cracks. It also allows water vapour pressure to be compensated for if there is residual moisture. DURABASE CI++ decouples the flooring from the foundations. Any small cracks can also be bridged so that they do not affect the tiling. This makes it ideal for renovation work. At mat joints, we recommend the use of sealing tape.

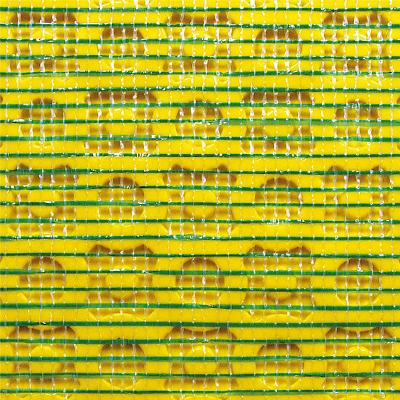

Due to the structure of the matting (nodules) channels are created, which also act to equalise water vapour pressures. With DURABASE CI++ the distribution of weight is handled by the texturing, which is filled in by thin-bed mortar. This means that loads can be spread out over the floor so that the tiles can withstand more stress if their thickness is sufficient. In very busy and highly stressed areas, the thickness of the tiles and their pressure resistance need to be selected appropriately for the location (at least 13 mm thick or more depending on the application).

Because of design, DURABASE-CI++ mats are not suitable for laying under thin or large-format floor tiles (”slimline tiles”). There is a risk of them breaking. In addition, small-format tiles under 50 x 50mm must not be used either.

Please Note: It is recommended to use a 4mm x 4mm notched Trowel to fix CI++ matting to the substrate.

Product Details:

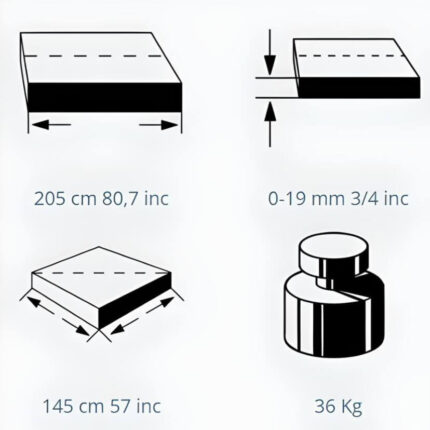

Size: 10m x 1m

Material: Textured foil = PP, Backing fleece = PP, Mesh = PP

Material Thickness: 0.5mm approximately

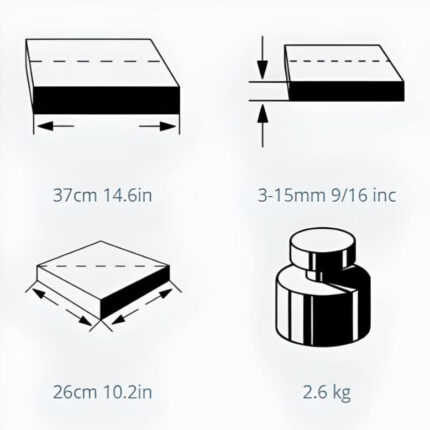

Mat Height: 3mm

Roll Width: 100cm

Compressive Strength: 0,37 N/mm² approximately

Temperature Range: 40 °C – + 80 °C

Colour Of Mats: Textured foil = yellow, backing fleece = white, mesh = green

Material Properties: Resistant to chemicals, decay, fungus and bacteria

Applications: Underlay matting for decoupling and compound sealing of tiled floors

Material Properties:

DURABASE CI++ matting is made of yellow polypropylene with a mesh fabric and a backing fleece which is also made of polypropylene. Thanks to this material composition, the mats are resistant to many different chemicals (e.g.: salts, acids and alkali) at low concentrations. For application areas under heavy chemical loading, a check of the chemical concentration, temperature and exposure time must be carried out prior to using the mats.

Suitable Surfaces:

– Cement screed

– Hot screeds

– Mastic asphalt screeds

– Concrete

– Synthetic laminates and coatings

– Plywood and chipboard

– Calcium sulphate screed (anhydrite screed)

– Wooden floorboards

Additional information

| Weight | 15 kg |

|---|---|

| Brand |

Durabase |